I was able to get mine, shipped, via Ali Express for about US$170, but it is also sold domestically (in the U.S.) from a number of vendors - sometimes under the brand name of "Chelegance".

A portable antenna is not the same as a "home" antenna

As you might expect, this antenna is intended for portable use - and easy-to-assemble, quickly-deployable antennas are not likely to offer high performance compared to their "ful-sized, high up in the tree" counterparts that you might have at your home QTH. Rather, this antenna's height is limited by the tripod on which it is mounted - which, for the lower bands where its height above ground is definitely below 1/4 wavelength - is likely to put it squarely in the "NVIS"(Near Vertical Incident Skywave) category - that is, an antenna with a rather high radiation angle that better-favors nearer stations than being a DX antenna.

Additionally, its element length as-shipped (with the two screw-in sections and the telescoping whip fully-extended, sans coil) is 125"(3.175 meters) is approximately a quarter-wavelength at 22MHz - near the 15 meter band meaning - that for all HF amateur bands 15 meters and below it requires the addition of the coils' inductance to resonate the two elements. Being a loaded antenna - and with a small-ish aperture and with coils losses - means that its efficiency IS going to be less than that of its full-sized antenna (e.g. half-wave dipole) counterpart.

Of course, the entire reason for using a "portable" antenna is to enjoy the convenience of an antenna that is quick to deploy and fairly easy to transport - and anyone doing this knows (or shouldknow) that one must often sacrifice performance when doing this!

Having said this, after using the JPC-7 in the field several times I've found that it holds up pretty well against a similar "full size" antenna (e.g. dipole) on the higher bands (20 and up) while on 40 meters, subjective analysis indicates that it's down by "about an S-unit". For SSB (voice) operation, this is usually tolerable under reasonable conditions and for digital or CW, it may hardly be noticeable.

|

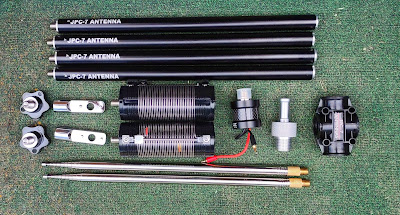

| Figure 2: The components included with the JPC-7 - except the strap and the manual. Click on the image for a larger version. |

What is included with the JPC-7:

- Four aluminum mast sections. These are hollow tubes with (pressed in?)

in screw fittings on the ends - one male and the other female, both

with M10-1.5 coarse threads that may be assembled piece-by-piece into a

mast/extension. End-to-end these measure 13-3/16"(33.5cm) each, including the protruding screw - 12-3/4"(32.4cm) from flat to flat. These are 3/4"(1.9cm) diameter. There are two of these sections per element to achieve the 125"(3.175 meter) length of each.

- Telescoping sections. These are stainless steel telescoping rods that are 13-1/8"(33.4cm) long including the threaded stud (12-7/8" or 32.7cm without) when collapsed and 99-11/16"(8' 3-11/16" or 253.2cm) when fully extended - not including the stud.

- Adjustable coils. These are constructed of what appears to be thermoplastic or possibly nylon with molded grooves for the wire. This unit is connected to the others via a male threaded stud on the bottom and female threads on the top, both being M10-1.5 like everything else.

- 5/8" stud (gaffer) mount. As mentioned earlier, this kit includes a male 5/8" stud mount commonly found on photographic lighting tripods. The other side of this has 1/2" NPT pipe threads that screw into the feedpoint mount. This piece is shown in Figure 4.

|

| Figure 4: 5/8 stud mount adapter to be used with lighting tripods. The "other" side is a 1/2 inch NPT pipe thread that screws into the feedpoint mount. Click on the image for a larger version. |

- 1:1 balun. This appears to be a "voltage" balun, with DC continuity between the "balanced" and "unbalanced" sections and across the windings themselves. This is in contrast to a "current" type balun that would typically consist of feedline, twisted pair or two conductors wound as a common-mode choke on a ferrite core. More on this later.

- Hook-and-loop ("Velcro") strap for the balun. This is used to attach the balun to the mast to prevent the weight of the coax and balun from pulling on the feedpoint mount. This strap appears to be generic and doesn't really fit the balun too well unless it is cinched up, so I zip-tied it in place to keep the two together.

- Padded carrying case. This zippered case is about 14" x 9"(35.5x23cm)

with elastic loops to retain the above antenna components and a

zippered "net" pocket to contain the counterpoise/radial cable kit and

the instructions. There is ample room in this case to add additional

components such as coaxial cable - and enhancements to the antenna, as

discussed below.

- Instruction manual. The instructions included with this antenna are only somewhat better than typical "Chinese English" - apparently produced with the help of an online translator rather than someone with intimate knowledge of the English language resulting in a combination of head-scratching, laughter and frustration when trying to make sense of them. Additionally, the instructions that came with my antenna included those for the JPC-12 vertical as well, printed on the obverse side of the manual.

Construction and build quality

About a year ago I purchased a JPC-12 vertical antenna and it shares many of the same components as this antenna - the only real differences are that this antenna comes with two telescoping whips and loading coils, the center mount for the elements, a 1:1 balun, and the 5/8" stud adapter for the center mount.

Many of these components are the same as supplied with the JPC-12 vertical: The loading coils, the telescoping whips, and the screw-together antenna sections. In other words, if you have both antennas, you can mix-match parts to augment the other. You can, in fact, buy kits of parts for either antenna to supply the missing pieces to convert from one to the other.

Mechanically, this antenna seems to be quite well built: During use, I have no sense of anything being "about to come apart" or "just barely good enough". I suspect that the designers of this antenna did so iteratively, and the end product is a result of some refinement over time. The only fragile parts are the telescoping whips, but these things are, by definition, fragile, no matter who makes them!

How it is mounted

This antenna does NOT come with any tripod or other support, but it offers three ways of being mounted:

- 1/2" NPT threads. The center support, as the primary mounting, has female 1/2" NPT threads.

- 5/8" male stud mount.

This antenna comes with a machined aluminum mount (seen in Figure 4) that screws into 1/2" NPT threads in the

center support that is a 5/8" stud mount - sometimes referred to as a

"Gaffer" or "Grip" mount - of the sort found everywhere on tripods used

for holding photographic lights.

- 10mm x 1.5mm thread.

If you want to configure this antenna as a dipole, you also have the option

of using a 10mm x 1.5mm thread that is on the side opposite the female

threads into which the 5/8" stud mount screws. While this thread isn't

particularly common in the U.S.A., it would seem that this is a common size for portable antennas everywhere else in the world and hardware of this size is available at larger U.S. hardware stores. As this mounting point may be used as part of the antenna

For

me the 5/8" male stud mount is the most useful as it happens that I have

onhand an old gaffer tripod (light stand) of this sort - but there's a catch: It,

too, has a 5/8"male stud mount! It would seem that these tripods come both ways - with

either a male or female 5/8" mount, but for less than US$15 I was able to

construct a "double-female" adapter that solved the problem. From Amazon, I ordered two 5/8 female stud to 3/8"-16 adapters and coupled them together with a 3/8" thread coupler as seen in Figure 5. The only "trick" with this was that I had to sort through my collection of flat washers to find the combination of thicknesses that resulted in both knobs facing the same direction when they were tightened.

Frequency coverage

This antenna is advertised to cover 40 through 6 meters - and this is certainly true: When the four supplied mast sections are installed (two per side) the lowest frequency at which it can be resonated with the telescoping rods at full extension and the inductors set at maximum is around 6.7-6.8 MHz - well below the entirety of the 40 meter band.

On 40 meters, the 2:1 VSWR bandwidth was typically around 150 kHz: A 2:1 VSWR is about the maximum mismatch at which most modern radios will operate at full power before SWR "foldback" occurs. Of course, if your radio has a built-in tuner - even one with a limited range - you will certainly be able to make the radio "happy" across the entire 40 meter band without fussing with the antenna.

On the other extreme, with the minimum coil inductance and the two telescoping rods at maximum the resonant frequency was about 21.7 MHz: This means that for all bands 15 meters and lower, you will need the inductors - but for 12 meters and up you can omit them entirely (which is recommended!), bringing the antenna to resonance solely by adjusting the length of the telescoping sections.

Tuning the antenna

This may be where some people have issues. I am very comfortable using a NanoVNA: I have several of these as they are both cheap and extremely useful - the only down-side really being that their screens are not easily viewed in direct sunlight - but simply standing with my back to the sun was enough to make it usable as all one is trying to see is the trace on the screen rather than any fine detail.

The biggest advantage of the NanoVNA over a traditional antenna analyzer is that you get the "big picture" of what is going on: You can instantly see where the antenna is resonant - and how good the match may be. More importantly, you can see at a glance if the antenna is tuned high (too little inductance) or too low (too much inductance) and make adjustments accordingly whereas using a conventional antenna analyzer will require you to sweep up and down: Still do-able, but less convenient.

Tuning is somewhat complicated by two factors:

- There are two coils to adjust - and they must both be pretty close to each other in terms of adjustment to get the best match. Simply looking at the coils one can "eyeball" the settings of the slider/contact to get them very close to each other - something that becomes easier with practice.

- The "resolution" of the inductors' adjustments is limited by the fact that one can make adjustments by one turn at a time. At 20 meters and higher, being able to only adjust inductance one turn at a time is likely to result in the best match being just above or below the desired frequency. At lower frequencies (lots of turns) - say 40 and 30 meters - you can likely get 2:1 or better by adjusting the coil taps alone, but at higher frequencies you will likely need to tune for the best match just below the frequency of interest and then shorten the telescoping rods slightly to bring it right onto frequency.

Once I'd used the antenna a few times I found that I could change bands in 2-3 minutes as I would:

- Lower the antenna to shoulder height so that the coils and telescoping rods may be reached. If you had previously shortened the telescoping elements for fine-tuning a band you should reset them to full length.

- Set the NanoVNA to cover from the frequency to which it is already tuned and where I want to go: If I was setting it up for the first time I would set the 'VNA to cover above and below the desired frequency by 5 MHz or so so I could see the resonant point even when it was far off-frequency. After using it a few times you will remember about where the coil taps need to be set for a particular band.

- On the NanoVNA I would then set a marker to the desired frequency.

- I would then "walk" both coils up/down to the desired frequency while watching the 'VNA. As the tuning of the elements interact, you may have to iterate a bit to get the VSWR down. Again, you may have to tune for best match at a frequency just below the target frequency and then shorten the telescoping sections.

- I would raise the mast to full height again. I noticed a slight increase in resonant frequency (particularly on the lower bands - 40 and 30 meters) by raising the antenna on the order of 50 kHz on 40 meters. Usually, this doesn't matter, but with a bit of practice/experience you'll be able to compensate for this while tuning.

- A match of 2:1 or better was easily obtained - but don't expect to get a 1:1 match all of the time as the only adjustments are those of resonating the elements. Practically speaking, there is no performance difference between a 2:1 and 1:1 match unless your radio's power drops back significantly: An antenna tuner could be used, but this will surely insert more loss than having a modest mismatch!

|

| Figure 6: As with almost any inductor adjustable using sliders, care should be taken to assure that only one turn is being touched by the contact, as shown. Click on the image for a larger version. |

Carefully adjusting coil taps

If you look very carefully at the sliding coil taps you'll notice that if very carefully adjusted that they will contact just one turn of wire - but it is almost easier for the contact spring to bridge two turns of wire, shorting them together. When this happens the inductance will go down slightly and you may see the resonance go up in frequency unexpectedly. Additionally, the shorting of two turns can also reduce the "Q"(and efficiency) of the coil slightly.

If you are aware of this situation - which can occur with nearly all tapped inductors adjusted with a slider - you can start to "feel" when the slider bridges two turns of the coil and avoid its happening as you make the adjustments.* * *

Suggested modifications/additions:

All electrically-short antennas that require series inductance for tuning to resonance - like this one - will lose efficiency due to losses in the coil, but this can be offset - at least somewhat - by increasing the length of the elements themselves. One of the easiest ways to do this is to purchase a couple of extra screw-on mast sections: The addition of one on each side will increase the total length by about 25"(64cm) and allow a slight decrease in the required inductance - resulting in slightly lower loss and increase the aperture of the antenna slightly. These additional screw-on sections are typically available from the sellers of the antenna for between US $10 and $15 each but are often called something like "Dedicated lengthened vibrator for JPC-7 (JPC-12)" or similar due to quirks of the translation.

While adding two additional sections will bring the resonant frequency down to about 5.7 MHz with full inductance and extension of the telescoping sections, the antenna can be made to cover 60 meters by clipping on short (18" or 46cm) jumper leads to the very end of the antenna elements and let them hang down. In testing it on the air, the signals were about 1 or 2 "S" units below a full-sized dipole, but still quite good for a fairly compact antenna that was close to the ground in terms of wavelength.

Of course these leads can be used for all bands for which the coils are needed to lower the inductance and reduce losses: As it will always be the parts of the antenna that carry the most RF current that radiates the vast majority of the signal - and since those portions will always be the sections right near the coils for this type of antenna - adding these dropping wires at the ends won't appreciably affect the antenna pattern or its polarization.

As there is plenty of room to do so in the zipper case, I have since added two extra sections and two "clip leads" permanently into the kit.

Finally, I would order at least two extra telescoping sections as these are the most fragile parts of the antenna kit. These can also be ordered from the same folks that sell the antennas for US $12-$16 each and are typically referred as something like "304 stainless steel 2.5M whip antenna for PAC-12 JPC7 portable shortwave antenna".

The reason for ordering two of them is that if the antenna falls over, both whips are likely to be damaged (ask me how I know!): The cost of getting two extra whips is likely to be less than the cost of fuel for even a modest road trip to wherever you are going, so their price should be kept in perspective. As the zippered case for the antenna has plenty of extra elastic loops inside, there is ready storage for these two extra whips with no modification.

A word of caution: However you store them, do not allow the telescoping whips to lay loosely: If they bash into something else they may be easily dented which can make it impossible for them to be extended/retracted. For this reason they should be secured in the elastic strap, or individually in a tubes or padded cases.

Note: There are also available much heavier and longer telescoping whips with the same M10x1.5 thread that would easily allow 60 meter coverage: I have not tried these to see how well they would work, mechanically, or if it would even be a good idea to do so (e.g. extra stress on the tubes, coils, mounting point - or how stable such a thing might be on a tripod).

Additional comments:

"To vee, or not to vee"

The feedpoint mount has a number of indexed holes that allow the elements to be mounted in a variety of configurations, from flat, in a number of "Vee" configurations, or even an "L" or vertical configuration.

Personally, I use the flattest "Vee" configuration as seen in Figures 8, 9 and 10. This configuration keeps the drooping ends of the telescoping whips higher than the feedpoint and helps clear any local obstacles (trees!) - and just looks cool!

As can be seen in Figure 8, the connection between the balun and the feedpoint is made by plugging 2.5mm miniature banana plugs into the brass receptacles on the feed. Shown in the photo are connections to the two sides, typically used for a dipole arrangement, but the third, unused connection on the top could be used to hold an element horizontal while one of the side connections hold it vertical - more on the use of this antenna as a vertical in the next section.

It should be no surprise that these 2.5mm miniature banana plugs are quite small and fragile and if one isn't careful - say, by allowing the weight of the balun to be supported by the wires rather than using the hook-and-loop strap - they can be broken. For this reason I ordered a pack of ten 2.5mm banana plugs from Amazon and made a pair of short (4", 10cm) leads - one end with a small alligator clip and the other with a 2.5mm banana plug - to allow me to make a temporary connection should one get broken off in the field - something that could torpedo an activation if you didn't have spare parts!

Operating as a vertical antenna

Because of the flexibility of the mounting point, it is possible to use this same kit as a vertical antenna with the second element as a resonant (rod) ground "plane" if - due to space or personal preference - emitting a signal with a vertically-polarized component is desired. While this will certainly "work", if you do plan to operate with vertical polarization its recommended that you add several (2 or more) wire "radials" or counterpoises.

Because of the included balun (more on this in a moment) the coaxial feedline itself will not act as an effective part of the counterpoise network so rather than connecting additional radials to the shield, the ends of the wire should be clamped under the washer/bolt that holds the horizontally-configured element in place. Of course, one need not use the balun and connect the coaxial cable directly, but if you choose this option you will be on your own to supply the means to make such a connection.

For best results with the fewest number of radials, choosing lengths that are odd-number quarter wavelengths long (1/4, 3/4, 5/4) and keeping them elevated a foot (25cm) or more off the ground is suggested as this will help minimize "ground" losses. Having said this, almost no matter what you do, you will probably be able to radiate a useful amount of signal: Operating CW or digital modes offers an improvement in "talk" capability owing to their efficiency - but if you are planning to operate SSB, it's worth taking a bit of extra time and effort to maximize performance.

Would I operate this antenna in "vertical" mode? While I don't have plans to do so, I have purchased an extra ground stake of the sort used on the JPC-12 vertical, and the short banana plug/clip lead jumpers that I made could be used to make a temporary connection directly to a coaxial connector.

Nature of the balun

The supplied balun has a 1:1 impedance ratio and has DC connection between the input and output - butsince there is a DC connection between all of the conductors, it is more than a simple current balun (e.g. transmission line wound on ferrite). As the balun seems to work well, I have no reason to break it open to figure out what's inside, but I did a bit of "buzzing" of the connections with a meter to measure inductance and here are the results:

- Between coax shield and center conductor: 16.9uH

- Between red and black (on antenna side): 16.9uH

- Between center coax and black: 38.5uH

- Between center and red: 3.4uH

- Between Shield and black: 3.4uH

- Between Shield and red: 3.4uH

- The DC resistance between any combination of the leads is well under 1 ohm.

What does this tell us? The inductance readings of about 16.9uH indicate that this may be a voltage balun providing about 500 ohms of inductive reactance at 5 MHz - more than enough for reasonable efficiency. The interesting reading is the inductance between the center coaxial connection and the black wire which is only twice the inductance of the input or output windings: If there was a direct connection between one of the coax and one of the output wires this would imply twice the number of turns and four times the inductance - but since it is only twice, this indicates that the total number of turns in the "center coax to black" route is about sqrt(2) (or 1.414x) as many turns as the primary/secondary - or there is another inductor in there.

|

| Figure 9: The JPC-7 backgrounded by red rock during a POTA operating in K-0010. Click on the image for a larger version. |

While I'm sure that the balun is very simple, its exact configuration/wiring escapes me at this time.

Coil losses

As mentioned earlier, the coil is wound with 18 AWG (1mm diameter) type 316 stainless steel wire. Fortunately, this wire appears is austenitic - which is to say that it is not of the variety that is magnetic and thus has a permeability of unity: Were it magnetic, this would negatively impact performance significantly.

Knowing the diameter of the coil form and the fact that there are 34 turns, we know that the total length of the wire used is approximately 180 inches (457cm) and measurement shows that the stainless steel wire coil has a total DC resistance of about 4 ohms. Using Owen Duffy's online skin effect calculator (link) and assuming 1mm diameter, 316 Stainless we can calculate the approximate RF resistance including skin effect - the tendency for RF to flow on the outside skin of a conductor rather than through its cross-section - versus frequency:

- 3.5 MHz = 5.2 ohms

- 7 MHz = 7.2 ohms

- 14 MHz = 9.6 ohms

- 28 MHz = 13.6 ohms

If was make a very broad assumption that the feedpoint resistance at each coil is about 25 ohms (the two in series being around 50 ohms) we can see that in this hypothetical situation about a third of the total resistance could be due to the coil, and since P = I2R - and if we presume that the current is consistent throughout the coil (it probably is not) we can roughly estimate that the total power loss will be proportional to the resistance implying that about 1/3rd of the total power is lost in the coil. In practical terms, a 33% power loss is around 4.8dB - still less than one "S" unit, so this loss may go unnoticed under typical conditions.

In operation, we would be unlikely to need all - or even most of the turns of the coil for operating on the higher bands, so the overall coil losses are likely to go down as the need for loading inductance at these frequencies is also significantly reduced: Since we actually use only about 2/3 of the turns of the coil on 40 meters, the loss is more likely to be something on the order of 5 ohms rather than 7.2, reducing the loss even more.

Note: K6STI's "coil" program - Link - calculates the loss for this coil as being closer to 8 than 5 ohms - a bit higher than the simple loss calculation of Owen Duffy's wire calculation and likely more representative of in-situ measurements.

When operating on 40 meters with 100 watts, the coils definitely do get quite warm - but not dangerously so and thus I would presume that the very rough estimates above are likely in the ballpark.

By comparison, the calculated DC resistance of the same length of 18 AWG bare copper wire is under 0.5 ohms, but the RF resistance due to skin effect at 28 MHz is around 2 ohms and about an ohm at 7 MHz - roughly a 7:1 difference meaning that if the above analysis is in any way close to being correct, our losses at 7 MHz when using the full coil (again, we don't!) and presuming that the feedpoint of the individual coil stayed at 25 ohms (it probably won't) our losses would drop from about 30% to less than 5%.

As a consequence, if wound with copper/silver plated I would expect that the not only would the antenna become narrower than the 40 meter 2:1 bandwidth of about 150 kHz - which would make it trickier to tune - I would also expect the feedpoint resistance to drop, possibly increasing the VSWR at the feedpoint. From a practical standpoint, even a modest antenna tuner capable of handling only 3:1 mismatch should be able to cope with this, but it is likely that some of the gains from using lower-loss wire might be offset by the increase in losses caused by feedline mismatch and the losses within a tuner - both of which could easily exceed 3dB in a portable set-up with moderately-long, small-diameter coax.

Would it be worth rewinding the coil with (readily-available) 18AWG (1mm dia) silver-plated or bare copper wire? Maybe. I obtained another adjustable coil from the same vendor and rewound it with 1mm diameter (18 AWG) silver-plated copper wire (readily available and used for making jewelry). I am in the process of running comparisons/tests and will produce a blog about that in the future.

Final comments

|

| Figure 10: Operating 20 meter CW from POTA entity K-6085, with the Conger mountains and the JPC-7 dipole in the background. Click on the image for a larger version. |

Is this an antenna that is worth getting? I would have to say "yes".

Remembering that you will also need to supply a suitable tripod mount (e.g. an inexpensive "light stand" ) this antenna is quite portable and, if you have a bit of practice, quick to set up and adjust. Unlike a vertical antenna, it doesn't need a set of ground radials and it is likely that the antenna itself will be up and above everyone's heads when it is deployed.

Best used on the higher bands (20 and higher) its efficiency will be quite good - certainly equal to or better than a typical mobile antenna. As this is a large-ish antenna on a tripod, be sure to weigh down the legs and/or attach simple guying to it to prevent it from blowing over in the wind or being knocked over by tripping over the coax: I can attest personally that the latter can easily happen!

I also have the JPC-12 vertical (which will be discussed in a future post) and I find this antenna (the JPC-7 loaded dipole, that is) to be far more convenient to use (no radial system), particularly if you plan to change bands several times during the operation - something that is quite likely to happen on the higher bands as propagation varies over the course of a few hours - as best performance requires adjusting the radials as well as the antenna itself, although it would probably work "just fine" if the radials are left at maximum length. Another advantage of this being a (largely) horizontally-polarized antenna is that in an urban environment it is likely to intercept less noise on receive than a vertical - and it can be inconspicuous in its deployment as compared to a taller vertical.

For the lower bands (40 and 30 meters) the JPC-7 works quite well - particularly if one operates CW or digital modes. As mentioned, it can also work competently on 60 meters as well with the addition of extra length of the elements by the purchasing of extra rods and/or simply attaching "drooping" wires to the ends of the telescoping rods.

Over the course of several POTA and related activation I have made about 500 contacts with this antenna on the band 60 through 15 meters - on CW and voice: I'm sure that the antenna works well on 12, 10 and 6 meters as well, but I just haven't tried it on those bands.

Overwhelmingly, the sense has been "If I can hear them, they can hear me." with this antenna as I have worked quite a few QRP and DX stations that I could barely copy above the band's natural QRN level. Admittedly, some of these times I was on the receiving end of the frenzy - being the activator during POTA operation - but there were many times when I had to stop operating not because I ran out of people to work, but because I ran out of time.

* * * * *

This page stolen from ka7oei.blogspot.com

[End]