As I'm wont to do, I occasionally go backpacking, carrying (a bit too much!) gear with me - some of it being electronic such as a camera, GPS receiver and ham radio(s). Because I'm usually out for a week or so - and also because I often have others with me that may also have battery-powered gear, there arises the need for a way to keep others' batteries charged as well.

Having done this for decades I've carried different panels with me over that time, wearing some of them out in the process, so it was time for a "refresh" and a new system using both more-current technology and based, in part, on past lessons learned.

Why 12 volt panels?

If you look about you'll find that there are a lot of panels nowadays that are designed to charge USB devices -which is fine if all you need to do is charge USB devices, but many cameras, GPS receivers, radios and other things aren't necessarily compatible with being charged from just 5 volts. The better solution in these cases is to start out with a higher voltage - say that from a "12 volt" panel intended for also keeping a car battery afloat - and convert it down to the desired voltage(s) as needed.

After a bit of difficulty in finding a small, lightweight panel that natively produced the raw "12 volts" output from the array (actually, 16-22 volts unloaded) I found a 18 watt folding panel that weighed just a bit more than a pound by itself. It happened to also include a USB charge socket - but can be hard to find one without that accessory!

By operating at "12 volts" you now have the choice of practically any charging device that can be plugged into a car's 12 volt accessory socket (e.g. cigarette lighter) and there are plenty of those about for nearly anything from AA/AAA chargers for things like GPS receivers and flashlights to those designed to charge your camera. An advantage of these devices is that nowadays, they are typically very small and lightweight, using switching power converters to take the panels voltage down to what is needed with relatively little loss.

But there is a problem.

If you use a switching power converter to take a high voltage down to a lower voltage, it will dutifully try to maintain a constant power output - which means that it will also attempt to maintain a constant power input as well - and this can lead to a vexing problem.

Take as an example of a switching power converter that is 100% efficient, charging a 5 volt device at 2 amps, or (5 volts * 2 amps =)10 watts.

If we are feeding this power converter with 15 volts, we need (10 watts / 15 volts =) 0.66 amps, but if we are supplying it with just 10 volts, we will need (10 watts / 10 volts =) 1 amp - all the way down to 2 amps at 5 volts. What this means is that while we always have 10 watts with these differing voltages, we will need more current as the voltage goes down.

Now suppose that we have a 15 watt solar panel. As is the nature of solar panels, there is a "magic" voltage at which our wattage (volts * amps) will be maximum, but there is also a maximum current that a panel will produce that remains more or less constant, regardless of the voltage. What this means is that if our panel can produce its maximum power at 15 volts where it is producing 1 amps, if we overload the panel slightly and cause its voltage to go down to, say, 10 volts, it will still be producing about 1 amp - but only making (10 volts * 1 amp =) 10 watts of power! Clearly, if we wish to extract maximum power to make the most of daylight we will want to pick the voltage at which we can get the maximum power.

Dealing with "stupid" power converters:

Suppose that, in our example, we are happily producing 10 watts of power to charge that 5 volt battery at 2 amps. At 15 volts, we need only 0.66 amps to get that 10 watts, but then a black cloud comes over and the panel can now produce only 0.25 amps. Because our switching converter is "stupid", it will always try to pull 10 watts - but when it does so, the voltage on its input, from the panel, will drop. In this scenario, our voltage converter will pull the voltage all of the way down to about 5 volts - but since the panel can only produce 0.25 amps, we will be charging with only (5 volts * 0.25 amps =)1.25 watts.

Now, the sun comes out - but the switching converter, being stupid, is still trying to pull 10 watts, but since it has pulled the voltage down to 5 volts to charge the battery, we will need 2 amps to feed the converter the 10 watts that it will need to be happy, but since our panel can never produce more than an amp, it will be stuck there, forever, producing about only (5 volts * 1 amp =) 5 watts.

If we were to disconnect the battery being charged momentarily so that the switching converter no longer saw its load and needed to try to output 10 watts, the input voltage would go back up to 15 volts - and then when we reconnected the battery, it would happily pull 0.66 amps at 15 volts again and resume charging the battery at 10 watts - but it will never"reset" itself on its own.

What this means is that you should NEVER connect a standard switching voltage converter directly to a solar panel or it will get "stuck" at a lower voltage and power if the available panel output drops below the required load - even for a moment!

Work-arounds to this "stuck regulator" problem:

The Linear regulator

One obvious work-around to this problem where a switching regulator gets "stuck" is to simply avoid using them, instead using an old-fashioned linear regulator such as an LM317 variable regulator or a fixed-voltage regulator in the 78xx series. This type of regulator, if outputting 1 amp, will also requite an input of 1 amp. If a black cloud comes over - or it is simply morning/evening with less light - and the panel outputs less current, that lower current will simply be passed along to the load.

The problem with a linear regulator is that it can be very inefficient, particularly if the voltage is being dropped significantly. For example, if you were to charge the 5 volt device at 1 amp from a panel producing 15 volts, your panel would be producing (15 volts * 1 amp =)15 watts, you would be charging your device at (5 volts * 1 amp =) 5 watts, but your linear regulator would be burning up 10 watts of heat, wasting most of the energy. On the up side, it simply cannot get "stuck" like a switching converter, it is very light, it will cause no radio interference, and it is nearly foolproof in its operation.

MPPT power controller

A better solution in terms of power utilization would be to use a more intelligent device such as an MPPT (Maximum Power Point Tracking) regulator. This is a "smarter" version of the switching regulator that, by design, avoids getting "stuck" by tracking how much power is actually available from the solar panel and never tries to pull more current than is available. For this discussion we'll talk about the two most common types of MPPT systems.

"Perturb and Observe" MPPT:

This method monitors both the current and voltage being delivered by the panel and internally, calculates the wattage (e.g. volts * amps) on the fly and under normal conditions, it will move the amount of current that it is trying to pull from the panel up and down slightly to see what happens, hence the name "Perturb and Observe"(a.k.a. "P&O").

For example, suppose that our goal is to get the maximum amount of power and our panel is producing 15 volts at 1 amp, or 15 watts. Now, the MPPT controller will try to pull, say, 1.1 amps from the panel. If the panel voltage drops slightly to 14.5 volts so we are now supplying (1.1 amps * 14.5 volts =) 15.95 watts and we were successful in pulling more power. Now, it will try again, this time to pull 1.2 amps from the panel, but it finds that when it does so, the panel voltage drops to 12.5 volts and we are now getting (1.2 amps * 12.5 volts =) 15 watts - clearly a decrease! Realizing its "mistake" it will quickly go back to pulling 1.1 amps to get back to the setting where it can pull more power. After this it may reduce its current to 1 amp again to "see" if things have changed and whether or not we can get more power - or if, perhaps, the amount of sunlight has dropped - such that trying to pull less current is the optimal setting.

By constantly "trying" different current combinations to see what provides the most power it will be able to track the different conditions that can affect power output of the solar panel - namely the amount of sun hitting it, the angle of that sun and to a lesser extent, the temperature of the solar panel.

"Constant Voltage" MPPT:

If you look at the current-versus-voltage curve of a typical solar panel as depicted in Figure 2 you'll note that there is a voltage at which the most power(volts * amps) can be produced(the squiggly vertical line)- a value typically around 70-80% of the open-circuit voltage, or somewhere in the area of 15-18 volts for a typical "12 volt" solar panel made these days.

Note:

One thing that you might notice is that, at least for higher amounts of light, the optimal voltage for maximum power is about the same - approximately 0.4 volts per cell. We can, therefore, design an MPPT circuit that is designed to cause the panel to operate only at that optimum voltage: If the sunlight is reduced and the voltage starts to drop, the circuit will decrease the current it is pulling, but if the sunlight increases and the voltage starts to rise, it will increase the current.

This method is simpler and cheaper than the "Perturb and Observe" method because one does not need to monitor the current from the panel (e.g. it cares only about the voltage) and there does not need to be a small computer or some sort of logic to keep track of the previous adjustments. For the Constant Voltage (e.g. "CV") method the circuit does only one thing: Adjust the current up and down to keep the panel voltage constant.

As can be seen from Figure 3, the method of using "one voltage for all situations" is not optimal for all conditions as the voltage at which the most power can be obtained changes with the amount of light, which also changes with the temperature of the panel, age, shading, etc. The end result of this rather simplistic method of optimization is that one ends up with somewhat lower efficiency overall - around 80% of the power that one might get with a well-performing P&O scheme according to some research.Ref. 1

This method can be optimized somewhat if the circuit is adjusted for maximum power output under "typical" conditions that one might encounter. For example, if the CV voltage is adjusted when the panel is under (more or less) maximum sun on a typical day, it will produce power most efficiently when the solar power production is at its highest and making the greatest contribution to the task at hand - such as charging a battery. In this case, it won't be as well optimized as well when the illumination is lower (e.g. morning or evening) but because the amount of energy available during these times will be lower anyway, a bit of extra loss from the lack of optimization at those times will be less significant than the same percentage of loss during peak production time.

Despite the lower efficiency, the Constant Voltage method is often found as a single-chip solution to implement low-cost MPPT, providing better performance than non-MPPT alternatives.

Actual implementation:

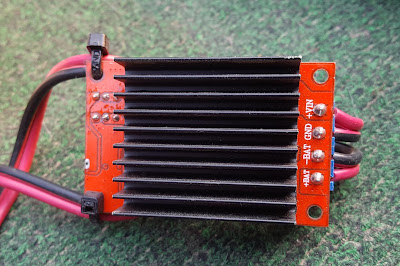

I was able to find an inexpensive (less than US$10, shipped) MPPT charge control board on EvilBay (called "5A MPPT Solar Panel Regulator Battery Charging") that was adjustable to allow its use with solar panels with open-circuit voltages ranging from 9 to 28 volts and its output being capable of being adjusted from 5 to about 17 volts. This small board had built-in current regulation set to a maximum of 5 amps - more than adequate for the 18 watt panel that I would be using.

From the pictures on the EvilBay posting - and also once I had it in-hand - I could see that it used the Consonance CN3722 MPPT chip. Ref. 2 This chip performs Constant Voltage (CV) MPPT functions and provides a current-regulated output with the components on the EvilBay circuit board limiting the current to a maximum of 5 amps. Additionally, this board, when used to charge a battery directly, could be adjusted, using onboard potentiometers, to be optimized for the solar panel's Maximum Power voltage (Vmp) and adjusted for the finish charge voltage for the battery itself, being suitable for many types of Lithium-Ion chemistries - including the "12 volt" LiFePO4 that I was going to use.

To this end, my portable charging system consists of the solar panel, this MPPT controller and a LiFePO4 battery to provide a steady bus voltage compatible with 12 volt chargers and devices. By including this battery, the source voltage for all of the devices being charged is constant and as long as the average current being pulled from the battery is commensurate with the average solar charging current, it will "ride through" wide variations in solar illumination. This method has the obvious advantage that a charge accumulated throughout the day can be used in the evening/night to charge those devices or even be used to top off batteries when one is hiking and the panel may not be deployed.

Tweaking the "Constant Voltage" MPPT board:

As noted, the EvilBay CN3722 board had two trimmer potentiometers: One for setting the output voltage - which would be the "finish" charge voltage for the battery and another for setting the Constant Voltage MPPT point for the panel to be used.

Setting the output voltage is pretty easy: After connecting it to a bench supply set for 4-6 volts above the desired voltage I connect a fairly light load to the output terminal and set it for the proper voltage. For a "12 volt" LiFePO4 battery, this will be between 14.2 and 14.6 volts while the setting for a more conventional "12 volt" LiIon battery would be between 16.2-16.8 volts, depending on the chemistry and desired finish voltage. Ref. 3 Once this adjustment has been done, I connected a fully-charged battery to the output along with a light load and power-cycled the MPPT controller and watched it, readjusting the voltage as necessary.

Setting the MPPT voltage is a bit tricker. In this case, a partially discharged battery of the same type and voltage that will be ultimately used as was adjusted above is connected to the output of the MPPT controller in series with an ammeter on the output. With the solar panel that is to be used connected and laid out in full sun, the "MPPT Voltage" potentiometer is adjusted for maximum current into the battery being charged. Again, this step requires a partially-discharged battery so that it will take all of the charging current that is available from the panel.

Note that the above procedure presumes that the solar panel is too small to produce enough power to cause the MPPT battery charger to go into current limiting - in which case, the current limit is that of the panel itself - which means that the maximum current that is seen at the charging terminal of the battery reflects the maximum power that can be pulled from the panel

If the panel is large enough to cause the MPPT controller to current-limit its charging current (around 5 amps for the MPPT controller that I used) then it may be that the panel is oversized slightly for the task - at least at midday, when there is peak sun. In that case one would make the same adjustment in the morning or evening when the amount of light was low enough that the panel could not cause the charger to current-limit or simply block a section of the panel.

While this charging board would be able to connect directly to almost any rechargeable Lithium battery, it would be awkward try to adapt it for each type of battery that one might need to charge so I decided to carry with me a small "12 volt" LiFePO4 battery as well: The solar panel and MPPT controller would charge that battery and then the various lightweight "12 volt" chargers for the different batteries to be charged would connect to it.

Its worth noting that MPPT power controllers use switching techniques to do the efficient conversion of voltage. What this means is that if, attached to - or nearby - is a sensitive radio - particularly an HF (shortwave) transceiver - the switching operation of the MPPT controller may cause interference unless the controller is enclosed in an RF-tight box with appropriate filtering on the input and output leads. In practice I haven't found this to be an issue as any HF operation is usually done in the evening, at camp, as things are winding down and the sun isn't out, anyway, so the unit is not in service at that time.

Final comments

While the "ballast battery" method has an obvious weight and volume penalty, it has the advantage that if you need to charge a number of different devices, it is possible to find a very small and light 12 volt "car" charger for almost any type of battery that you can imagine. The other advantage is that with a 12 volt battery that is being charged directly from the MPPT controller, it acts as "ballast", allowing the charging of this "main" battery opportunistically with the available light as well as permitting the charging of the other batteries at any time - including overnight!

The 18 watt panel weighs 519 grams (1.14 pounds), the MPPT charge controller with attached wires and connectors weighs 80 grams (0.18 pounds), a cable connecting the panel to the MPPT controller weights 60 grams (0.13 pounds) while the 6-7 amp-hour LiFePO4 battery pictured in Figure 1 weighs in at 861 grams (1.9 pounds). The total weight of this power system is about 1520 grams (3.35 pounds) - which can be quite a bit to carry in a backpack, but considering that it can provide the power needs of a fairly large group and that this weight can be distributed amongst several people, if necessary, it is "tolerable" for all but those occasions where it is imperative that there is the utmost in weight savings. For a "grab and go" kit that will be transported via a vehicle and carried only a short distance this amount weight is likely not much of an issue.

1 - The article "Energy comparison of MPPT techniques for PV Systems" - link - describes several MPPT schemes, how they work, and provides comparison as to how they perform under various (simulated) conditions.

2 - Consonance Electric CN3722 Constant Voltage (CV) MPPT multichemistry battery charger/regulator - Datasheet link.

3 - Particularly true for LiIon cells, reducing the finish (e.g. cut off) voltage by 5-10%, while reducing the available cell capacity, can improve the cell's longevity. What this means is that if the cut-off voltage of a typical modern LiIon cell, which is nominally 4.2 volts, is reduced to 4.0 volts, all other conditions being equal this can have the potential to double the useful working life. While this lower cut off voltage may initially reduce the available capacity by as much as 25%, a cell consistently charged to the full 4.2 volts will probably lose this much capacity in a year or so, anyway whereas it will lose much less capacity than that at the lower voltage. For additional information regarding increasing the longevity of LiIon cells see the Battery University web page "How to Prolong Lithium-based Batteries" - link and its reference sources.

[End]

This page stolen from "ka7oei.blogspot.com".

Having done this for decades I've carried different panels with me over that time, wearing some of them out in the process, so it was time for a "refresh" and a new system using both more-current technology and based, in part, on past lessons learned.

Why 12 volt panels?

If you look about you'll find that there are a lot of panels nowadays that are designed to charge USB devices -which is fine if all you need to do is charge USB devices, but many cameras, GPS receivers, radios and other things aren't necessarily compatible with being charged from just 5 volts. The better solution in these cases is to start out with a higher voltage - say that from a "12 volt" panel intended for also keeping a car battery afloat - and convert it down to the desired voltage(s) as needed.

After a bit of difficulty in finding a small, lightweight panel that natively produced the raw "12 volts" output from the array (actually, 16-22 volts unloaded) I found a 18 watt folding panel that weighed just a bit more than a pound by itself. It happened to also include a USB charge socket - but can be hard to find one without that accessory!

By operating at "12 volts" you now have the choice of practically any charging device that can be plugged into a car's 12 volt accessory socket (e.g. cigarette lighter) and there are plenty of those about for nearly anything from AA/AAA chargers for things like GPS receivers and flashlights to those designed to charge your camera. An advantage of these devices is that nowadays, they are typically very small and lightweight, using switching power converters to take the panels voltage down to what is needed with relatively little loss.

But there is a problem.

If you use a switching power converter to take a high voltage down to a lower voltage, it will dutifully try to maintain a constant power output - which means that it will also attempt to maintain a constant power input as well - and this can lead to a vexing problem.

Take as an example of a switching power converter that is 100% efficient, charging a 5 volt device at 2 amps, or (5 volts * 2 amps =)10 watts.

If we are feeding this power converter with 15 volts, we need (10 watts / 15 volts =) 0.66 amps, but if we are supplying it with just 10 volts, we will need (10 watts / 10 volts =) 1 amp - all the way down to 2 amps at 5 volts. What this means is that while we always have 10 watts with these differing voltages, we will need more current as the voltage goes down.

Now suppose that we have a 15 watt solar panel. As is the nature of solar panels, there is a "magic" voltage at which our wattage (volts * amps) will be maximum, but there is also a maximum current that a panel will produce that remains more or less constant, regardless of the voltage. What this means is that if our panel can produce its maximum power at 15 volts where it is producing 1 amps, if we overload the panel slightly and cause its voltage to go down to, say, 10 volts, it will still be producing about 1 amp - but only making (10 volts * 1 amp =) 10 watts of power! Clearly, if we wish to extract maximum power to make the most of daylight we will want to pick the voltage at which we can get the maximum power.

Dealing with "stupid" power converters:

Suppose that, in our example, we are happily producing 10 watts of power to charge that 5 volt battery at 2 amps. At 15 volts, we need only 0.66 amps to get that 10 watts, but then a black cloud comes over and the panel can now produce only 0.25 amps. Because our switching converter is "stupid", it will always try to pull 10 watts - but when it does so, the voltage on its input, from the panel, will drop. In this scenario, our voltage converter will pull the voltage all of the way down to about 5 volts - but since the panel can only produce 0.25 amps, we will be charging with only (5 volts * 0.25 amps =)1.25 watts.

Now, the sun comes out - but the switching converter, being stupid, is still trying to pull 10 watts, but since it has pulled the voltage down to 5 volts to charge the battery, we will need 2 amps to feed the converter the 10 watts that it will need to be happy, but since our panel can never produce more than an amp, it will be stuck there, forever, producing about only (5 volts * 1 amp =) 5 watts.

If we were to disconnect the battery being charged momentarily so that the switching converter no longer saw its load and needed to try to output 10 watts, the input voltage would go back up to 15 volts - and then when we reconnected the battery, it would happily pull 0.66 amps at 15 volts again and resume charging the battery at 10 watts - but it will never"reset" itself on its own.

What this means is that you should NEVER connect a standard switching voltage converter directly to a solar panel or it will get "stuck" at a lower voltage and power if the available panel output drops below the required load - even for a moment!

Work-arounds to this "stuck regulator" problem:

The Linear regulator

One obvious work-around to this problem where a switching regulator gets "stuck" is to simply avoid using them, instead using an old-fashioned linear regulator such as an LM317 variable regulator or a fixed-voltage regulator in the 78xx series. This type of regulator, if outputting 1 amp, will also requite an input of 1 amp. If a black cloud comes over - or it is simply morning/evening with less light - and the panel outputs less current, that lower current will simply be passed along to the load.

The problem with a linear regulator is that it can be very inefficient, particularly if the voltage is being dropped significantly. For example, if you were to charge the 5 volt device at 1 amp from a panel producing 15 volts, your panel would be producing (15 volts * 1 amp =)15 watts, you would be charging your device at (5 volts * 1 amp =) 5 watts, but your linear regulator would be burning up 10 watts of heat, wasting most of the energy. On the up side, it simply cannot get "stuck" like a switching converter, it is very light, it will cause no radio interference, and it is nearly foolproof in its operation.

MPPT power controller

A better solution in terms of power utilization would be to use a more intelligent device such as an MPPT (Maximum Power Point Tracking) regulator. This is a "smarter" version of the switching regulator that, by design, avoids getting "stuck" by tracking how much power is actually available from the solar panel and never tries to pull more current than is available. For this discussion we'll talk about the two most common types of MPPT systems.

"Perturb and Observe" MPPT:

This method monitors both the current and voltage being delivered by the panel and internally, calculates the wattage (e.g. volts * amps) on the fly and under normal conditions, it will move the amount of current that it is trying to pull from the panel up and down slightly to see what happens, hence the name "Perturb and Observe"(a.k.a. "P&O").

For example, suppose that our goal is to get the maximum amount of power and our panel is producing 15 volts at 1 amp, or 15 watts. Now, the MPPT controller will try to pull, say, 1.1 amps from the panel. If the panel voltage drops slightly to 14.5 volts so we are now supplying (1.1 amps * 14.5 volts =) 15.95 watts and we were successful in pulling more power. Now, it will try again, this time to pull 1.2 amps from the panel, but it finds that when it does so, the panel voltage drops to 12.5 volts and we are now getting (1.2 amps * 12.5 volts =) 15 watts - clearly a decrease! Realizing its "mistake" it will quickly go back to pulling 1.1 amps to get back to the setting where it can pull more power. After this it may reduce its current to 1 amp again to "see" if things have changed and whether or not we can get more power - or if, perhaps, the amount of sunlight has dropped - such that trying to pull less current is the optimal setting.

By constantly "trying" different current combinations to see what provides the most power it will be able to track the different conditions that can affect power output of the solar panel - namely the amount of sun hitting it, the angle of that sun and to a lesser extent, the temperature of the solar panel.

|

| Figure 3: Curves showing the voltage versus current of a typical solar cell. Once the current goes above a certain point, the voltage output of a cell drops dramatically. The squiggly, vertical line indicates where the maximum power (e.g. volts * amps) is obtained along the curve. The upper graphs depict a typical curve with larger amounts of light while the lower graphs are for smaller amounts of impinging light. This graph is from the Wikipedia article about MPPT - link. Click on the image for a slightly larger version. |

If you look at the current-versus-voltage curve of a typical solar panel as depicted in Figure 2 you'll note that there is a voltage at which the most power(volts * amps) can be produced(the squiggly vertical line)- a value typically around 70-80% of the open-circuit voltage, or somewhere in the area of 15-18 volts for a typical "12 volt" solar panel made these days.

Note:

Many "12 volt" panels currently being made are intended for use with MPPT controllers and have a bit of extra voltage "overhead" as compared to "12 volt" panels made many years ago before MPPT charging regimens were common. What this means is that a modern "12 volt" panel may have an maximum power point voltage of 16-17 volts as opposed to 14-15 volts for an "older" panel made 10+ years ago.

One thing that you might notice is that, at least for higher amounts of light, the optimal voltage for maximum power is about the same - approximately 0.4 volts per cell. We can, therefore, design an MPPT circuit that is designed to cause the panel to operate only at that optimum voltage: If the sunlight is reduced and the voltage starts to drop, the circuit will decrease the current it is pulling, but if the sunlight increases and the voltage starts to rise, it will increase the current.

This method is simpler and cheaper than the "Perturb and Observe" method because one does not need to monitor the current from the panel (e.g. it cares only about the voltage) and there does not need to be a small computer or some sort of logic to keep track of the previous adjustments. For the Constant Voltage (e.g. "CV") method the circuit does only one thing: Adjust the current up and down to keep the panel voltage constant.

As can be seen from Figure 3, the method of using "one voltage for all situations" is not optimal for all conditions as the voltage at which the most power can be obtained changes with the amount of light, which also changes with the temperature of the panel, age, shading, etc. The end result of this rather simplistic method of optimization is that one ends up with somewhat lower efficiency overall - around 80% of the power that one might get with a well-performing P&O scheme according to some research.Ref. 1

This method can be optimized somewhat if the circuit is adjusted for maximum power output under "typical" conditions that one might encounter. For example, if the CV voltage is adjusted when the panel is under (more or less) maximum sun on a typical day, it will produce power most efficiently when the solar power production is at its highest and making the greatest contribution to the task at hand - such as charging a battery. In this case, it won't be as well optimized as well when the illumination is lower (e.g. morning or evening) but because the amount of energy available during these times will be lower anyway, a bit of extra loss from the lack of optimization at those times will be less significant than the same percentage of loss during peak production time.

Despite the lower efficiency, the Constant Voltage method is often found as a single-chip solution to implement low-cost MPPT, providing better performance than non-MPPT alternatives.

Actual implementation:

I was able to find an inexpensive (less than US$10, shipped) MPPT charge control board on EvilBay (called "5A MPPT Solar Panel Regulator Battery Charging") that was adjustable to allow its use with solar panels with open-circuit voltages ranging from 9 to 28 volts and its output being capable of being adjusted from 5 to about 17 volts. This small board had built-in current regulation set to a maximum of 5 amps - more than adequate for the 18 watt panel that I would be using.

From the pictures on the EvilBay posting - and also once I had it in-hand - I could see that it used the Consonance CN3722 MPPT chip. Ref. 2 This chip performs Constant Voltage (CV) MPPT functions and provides a current-regulated output with the components on the EvilBay circuit board limiting the current to a maximum of 5 amps. Additionally, this board, when used to charge a battery directly, could be adjusted, using onboard potentiometers, to be optimized for the solar panel's Maximum Power voltage (Vmp) and adjusted for the finish charge voltage for the battery itself, being suitable for many types of Lithium-Ion chemistries - including the "12 volt" LiFePO4 that I was going to use.

To this end, my portable charging system consists of the solar panel, this MPPT controller and a LiFePO4 battery to provide a steady bus voltage compatible with 12 volt chargers and devices. By including this battery, the source voltage for all of the devices being charged is constant and as long as the average current being pulled from the battery is commensurate with the average solar charging current, it will "ride through" wide variations in solar illumination. This method has the obvious advantage that a charge accumulated throughout the day can be used in the evening/night to charge those devices or even be used to top off batteries when one is hiking and the panel may not be deployed.

Tweaking the "Constant Voltage" MPPT board:

As noted, the EvilBay CN3722 board had two trimmer potentiometers: One for setting the output voltage - which would be the "finish" charge voltage for the battery and another for setting the Constant Voltage MPPT point for the panel to be used.

Setting the output voltage is pretty easy: After connecting it to a bench supply set for 4-6 volts above the desired voltage I connect a fairly light load to the output terminal and set it for the proper voltage. For a "12 volt" LiFePO4 battery, this will be between 14.2 and 14.6 volts while the setting for a more conventional "12 volt" LiIon battery would be between 16.2-16.8 volts, depending on the chemistry and desired finish voltage. Ref. 3 Once this adjustment has been done, I connected a fully-charged battery to the output along with a light load and power-cycled the MPPT controller and watched it, readjusting the voltage as necessary.

Setting the MPPT voltage is a bit tricker. In this case, a partially discharged battery of the same type and voltage that will be ultimately used as was adjusted above is connected to the output of the MPPT controller in series with an ammeter on the output. With the solar panel that is to be used connected and laid out in full sun, the "MPPT Voltage" potentiometer is adjusted for maximum current into the battery being charged. Again, this step requires a partially-discharged battery so that it will take all of the charging current that is available from the panel.

Note that the above procedure presumes that the solar panel is too small to produce enough power to cause the MPPT battery charger to go into current limiting - in which case, the current limit is that of the panel itself - which means that the maximum current that is seen at the charging terminal of the battery reflects the maximum power that can be pulled from the panel

If the panel is large enough to cause the MPPT controller to current-limit its charging current (around 5 amps for the MPPT controller that I used) then it may be that the panel is oversized slightly for the task - at least at midday, when there is peak sun. In that case one would make the same adjustment in the morning or evening when the amount of light was low enough that the panel could not cause the charger to current-limit or simply block a section of the panel.

While this charging board would be able to connect directly to almost any rechargeable Lithium battery, it would be awkward try to adapt it for each type of battery that one might need to charge so I decided to carry with me a small "12 volt" LiFePO4 battery as well: The solar panel and MPPT controller would charge that battery and then the various lightweight "12 volt" chargers for the different batteries to be charged would connect to it.

Its worth noting that MPPT power controllers use switching techniques to do the efficient conversion of voltage. What this means is that if, attached to - or nearby - is a sensitive radio - particularly an HF (shortwave) transceiver - the switching operation of the MPPT controller may cause interference unless the controller is enclosed in an RF-tight box with appropriate filtering on the input and output leads. In practice I haven't found this to be an issue as any HF operation is usually done in the evening, at camp, as things are winding down and the sun isn't out, anyway, so the unit is not in service at that time.

Final comments

While the "ballast battery" method has an obvious weight and volume penalty, it has the advantage that if you need to charge a number of different devices, it is possible to find a very small and light 12 volt "car" charger for almost any type of battery that you can imagine. The other advantage is that with a 12 volt battery that is being charged directly from the MPPT controller, it acts as "ballast", allowing the charging of this "main" battery opportunistically with the available light as well as permitting the charging of the other batteries at any time - including overnight!

The 18 watt panel weighs 519 grams (1.14 pounds), the MPPT charge controller with attached wires and connectors weighs 80 grams (0.18 pounds), a cable connecting the panel to the MPPT controller weights 60 grams (0.13 pounds) while the 6-7 amp-hour LiFePO4 battery pictured in Figure 1 weighs in at 861 grams (1.9 pounds). The total weight of this power system is about 1520 grams (3.35 pounds) - which can be quite a bit to carry in a backpack, but considering that it can provide the power needs of a fairly large group and that this weight can be distributed amongst several people, if necessary, it is "tolerable" for all but those occasions where it is imperative that there is the utmost in weight savings. For a "grab and go" kit that will be transported via a vehicle and carried only a short distance this amount weight is likely not much of an issue.

* * *

References:1 - The article "Energy comparison of MPPT techniques for PV Systems" - link - describes several MPPT schemes, how they work, and provides comparison as to how they perform under various (simulated) conditions.

2 - Consonance Electric CN3722 Constant Voltage (CV) MPPT multichemistry battery charger/regulator - Datasheet link.

3 - Particularly true for LiIon cells, reducing the finish (e.g. cut off) voltage by 5-10%, while reducing the available cell capacity, can improve the cell's longevity. What this means is that if the cut-off voltage of a typical modern LiIon cell, which is nominally 4.2 volts, is reduced to 4.0 volts, all other conditions being equal this can have the potential to double the useful working life. While this lower cut off voltage may initially reduce the available capacity by as much as 25%, a cell consistently charged to the full 4.2 volts will probably lose this much capacity in a year or so, anyway whereas it will lose much less capacity than that at the lower voltage. For additional information regarding increasing the longevity of LiIon cells see the Battery University web page "How to Prolong Lithium-based Batteries" - link and its reference sources.

[End]

This page stolen from "ka7oei.blogspot.com".