There are projects that homebrewers undertake that seem not to make sense when one considers the amount of time that it takes to do that thing - but then again, this is often the case when one builds projects at home, from "scratch". The case in point for this discussion is the winding of power transformers and chokes.

I am not an expert in this so what follows is, among other things, the documentation of the learning experience: No doubt I will make mistakes along the way, but analysis of these mistakes and observations will (hopefully) be enlightening.

Why?

For some reason I have decided to go "old school" and, along with a friend (Bryan, W7CBM) we will each construct a two-channel single-ended triode audio amplifier using some old WWII vintage tubes (the details on this amplifier to be detailed in a later post.) To be clear, I'm not of the sort that really believes that the "tube sound" is best for various intangible reasons - in fact, I'm expecting that if it works better than expected, its performance will be worse than practically any other modern audio amplifier that I have in the ways that matter to most people (e.g. power efficiency, noise, hum, distortion, frequency flatness, phase - just name it!)

As it is often the case with a project like this, practicality is somewhat irrelevant: It is the experience of doing something that you have never done before - and learning from it - that will be the reward whether or not the project is ultimately successful. To be sure there will not likely be a cost savings in doing this and there certainly will not a time savings!

Diving into this project, we decided to do something that I'd not done for many years: Wind my own power transformers and chokes. As for the audio output transformers for this audio project we decided to forgo that task and get "store bought", proven transformers given our current level of experience.

Where to find useful information:

Interestingly, scant useful and credible information seems to be available on the GoogleWeb on this topic, but two sources that are useful are:

A few other bits and pieces of information have been found but the above two seem to be some of the best, both written by people who have years of practical experience - and the pages include additional references to other sources.

Rummaging through some old amateur radio and electronics books I have been able to divine other details as well, but much of this information is rather generic and doesn't speak much about the use and capabilities of modern types of wire, insulation or core materials.

Getting the gear together:

Made mostly from cast steel, this device is about as simple as it can get: It has some gears that provide an 8:1 ratio for the hand crank (e.g. one revolution of the crank = 8 turns on the coil), a 5-digit turns counter (0-99999) and a spindle on which one would mount the bobbin, and it seems to be built "well enough" for the purpose, likely to last many hundreds of thousands of revolutions. This device has no wire-handling capability (e.g. nothing to hold the spool, guide the wire or provide tension) so those pieces would have to be constructed and/or improvised.

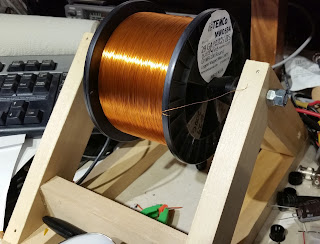

After the NZ-1 arrived I bolted it to a block of wood and for wire handling of the supply spool I made a simple wooden "A" frame holder (Figure 3), placing it on the workbench behind the winding machine.

By default, the crank is connected to a shaft that, via gears, results in eight turns on the coil with one turn of the crank. For practical reasons, winding a core like this needs a bit more precision and control and a 1:1 ratio is desired and the obvious place to relocate the crank is the upper shaft with the pulley, visible in Figure 2 on the upper-right corner of the winding machine.

While the shaft size is the same, attaching the crank at this point caused the crank's handle to hit the lower shaft to which the crank is usually connected! Fortunately I could attach the crank to the very end of the shaft and have it just barely clear the lower shaft where the crank would normally be attached for the 8:1 ratio: At some point I'll have made a metal piece made that will extend the shaft by a half inch (approximately 1cm) or so.

Also very important is the bobbin holder (Figure 4) constructed from scraps of paneling and "1x2" pieces of poplar. Because the core size is "E150" - which stands for "1.5", two pieces 1x2 wood (which are really 0.75"x1.5") fit very nicely within the bobbin. Glued to the end of the bobbin holder on one side is a scrap of paneling as an end-stop while on the other side, oriented by two finishing nails used as pins, are two more pieces of 1x2 glued together as the "other" end stop. Both the bobbin and the removable end stop are marked to provide a means of orienting the four faces of the bobbin and the removable piece also sports two screws around which wires that are brought out from the bobbin may be wound to keep them out of the way. Two more blocks of wood, cut to the internal length of the bobbin, are also available to compress the "bulge" that inevitably forms as wire is wound. Through the center of the bobbin holder was drilled a hole of the size appropriate to allow it to be slipped over the shaft of the winding machine. When mounted, the bobbin holder is held in by compression of the nut and it does not easily turn on its own.

While not the most elegant of solutions, this arrangement seems to work - provided that one takes care to prevent "overfeeding" of the wire and subsequent possible tangling of off-spooled wire caused by the inconsistent feed rate as one winds onto a square bobbin and the supply wire occasionally tries to wind itself around the piece of "allthread" on which the spool hangs!

The most important aspects of this minimal arrangement are:

Because a choke is "simpler" to wind than a transformer, I decided to start with that.

The design goal of the choke was to provide at least 10 Henries of inductance with a current capacity of at least 200mA. The general rule of thumb for a modest-sized transformer or choke is to size the wire to 0.3 to 0.4 mm2 per amp (from references 1 and 2, above) which would imply that for 200mA the minimum wire would need a cross-sectional area of around 0.06mm2 which corresponds to #29 AWG.

Now we need to figure out (approximately) how many turns can fit on our bobbin.

The E150 bobbin that I would be using has an inside dimension of 41.5mm on a side and an outside dimension of 75.4mm on a side with a "width" of 53.3mm and based on this we calculate that the area of the bobbin's window is approximately 53mm wide and 17mm high, or about 901mm2.

Because the cross sectional area of #29 AWG wire, based on a 0.33mm diameter with insulation, is 0.086mm2 this implies that we could theoretically put around 10477 pieces of wire (or turns) in this 109mm2 space. Practically speaking, this is simply not possible since there is always going to be some "wastage" based on the fact that we will be laying round wires next to each other and there will be gaps in between. Typically, one would scale this calculation by a "fill factor" to accommodate such wastage with this factor typically being around 0.4 (e.g. 4191 turns) or as high as 0.5 (5239 turns) if one winds extremely carefully and neatly - and assuming no added insulation: Less careful winding can easily result in "fill factors" lower than 0.4.

Breaking this down differently we can calculate that across the width of the bobbin we should (theoretically) be able to put (53mm/0.33mm = 161) turns on each layer, but taking into account the practicalities of being able to get wire to lie snugly next to its neighbor we can more reasonably expect to achieve around 95% of this, or about 153 turns per layer - maybe slightly more if we are fastidious.

Since our bobbin window is 17mm "tall" we could theoretically expect to be able to stack 51 layers of 0.33 thick wire, but this also assumes both "perfect" stacking efficiency and the lack of any inter-layer insulation. If we presume that each layer contains a 0.33mm thickness of wire and 0.05mm thickness of insulation - a total of 0.38mm - we can then recalculate that it would take about (17/0.38) 44 layers of windings to fill the bobbin - again, assuming perfect stacking and no need for additional insulation.

For practical reasons we would want to fill our bobbin to only 70-90% "fullness" in order to be able to add the final covering insulation and connecting wires, so this would take or maximum layer count down to between 30 and 39 layers - again, assuming that we didn't need extra insulation anywhere.

If we take an average of 153 turns per layer, we could reasonably expect be able to put between 4590 and 5957 turns on this bobbin. Taking a median per-turn length of wire on the bobbin to be around 234 mm based on the size of the bobbin itself we can estimate that we'll need between 1074 and 1394 meters, or between 28 and 37% of our 5 pound spool.

Comment:

Starting the wind:

With the necessary parts (bobbins and core material being "E150" types from Edcor, the wire and polyimide insulating tape from other sources) I began to wind a choke - the simplest of the devices and (hopefully) hardest to screw up!

The general advice on winding transformers seems to be that it is best to assure that all wires are laid side-by-side on nice, even layers. By doing this one avoids one turn from crossing another and putting tremendous point-pressure on the insulation of the two wires as they cross. This advice hales from the days when wire was insulated with simple, comparatively fragile varnish that could be easily penetrated from vibration due to hum and thermally-related movement and by its softening at higher temperatures, but these days wire is available with much more durable insulation, so it seems to be permissible, with chokes, anyway, to allow wires to cross at shallow angles.

Since this was my first large power choke choke I decided to take the "neat, even layer" approach for the most part, but what this meant was that during each and every turn I would have to watch exactly where the wire turn lay, often scrunching it close to its neighbor if it shifted away and "un-crossing" it if it happened to overlay another. This also meant that after I finished winding every layer of approximately 150-156 turns I had to stop, temporarily tape the source wire to the bobbin to keep in from unraveling, apply a layer of 2-mil (0.5mm) polyimide tape over the top of the layer and then resume winding.

As is the case with such things, it is a bit more difficult than one might at first expect. For the first several layers I had to contend with the "lump" and the "gap" at the "start" end of the bobbin where the external wire was attached and I did this by filling in the void with very thin strips of cardboard laid down to match the width and height of the heavier, connecting wire. After several layers, the layers equaled the height of this "lump" and with the matching thickness of the cardboard strips, it disappeared, allowing me to more easily wind across the entire width.

After a dozen or so layers the windings started to form "ripples" caused largely by the fact that the polyimide tape overlapped in approximately the same place each time - a problem exacerbated by the fact that I had, at the time, only one width of tape, limiting the degree to which I could "stagger" the overlap. The biggest problem with this was not necessarily asthetics, but the fact that the as the wire was wound it tended to slip into the trough of the ripple, making it very difficult to maintain evenness and the nice, side-by-side wire lay for which I was striving and with each layer, these irregularities grew!

What I had to do was to fold over some of the tape in half (sticky side facing outwards) to fill in some of the dips and on the square "corners" of the bobbin I started to strategically add small bits of tape to level it out as it was there that the slippage was most likely to occur. As I got into 10s of layers, some of the troughs seemed to resist the attempts at leveling so I carefully resorted to putting several turns of wire atop each other at shallow angles to help even the surface: Only a tiny fraction of the turns are wound in this way.

The lesson here is to have on hand multiple widths of tape so that the overlaps may be staggered. What would have also been handy would have been to have on-hand some pieces of MNM ("Nomex" (tm)) insulating sheets to cut into strips to fill the voids. It would have also been very help to have some tape that was exactly as wide as the bobbin, but such a specific width is not likely to be commercially available.

The results:

Based on the DC resistance - around 277 ohms - this represents approximately 3384 feet (1031 meters) of wire - a bit more than a quarter of the 5 pound spool. Carefully drilling another hole in the bobbin I attached the "finish" wire to the outside of the coil, insulated it and taped it securely into place.

By itself (no core) the inductance of the 4905 turns on the bobbin measured out at approximately 884 millihenries and when the core was installed - butt-stacked, but not carefully aligned - this increased to over 110 Henries: If I had carefully interleaved all 109 E-I laminations and properly seated each piece this value would have likely been much higher!

Preventing core saturation:

Because this is intended to be used as part of a "choke input" high voltage power supply one must take into account the fact that DC current will flow through the choke, magnetizing the core material. One property of practically any ferromagnetic material - including the steel used in the core of this choke - is that if the magnetic field exceeds a certain point, the core will saturate and the permeability (and the inductance) will drop! While there are chokes that are designed to do this (e.g. "swinging" chokes - those that have inductance that, by design, drops with increased current) it was desired that this choke's inductance be more consistent.

The most common way to control this effect is to intentionally reduce the permeability of the core overall by the introduction of an air gap which breaks up the magnetic lines of force: The larger the gap, the greater the reduction. The trick here is to reduce the permeability - and thus the level of magnetization - to the level that the core does not saturate at the desired current, but not too much more.

Fortunately, there are some equations that help us calculate things like this. Knowing that the core material that I am using ("M6" Grain-Oriented Silicon Steel) will safely operate at 1.6-1.7 Tesla (16000-17000 Gauss) I could crunch some numbers based on what I already knew.

Taking the following equation from link #1 (the Turner audio web pages), above:

uE = (109 * ML * L) / (T2 * Afe)

Where:

With the temporary butt-stacked arrangement (e.g. full of small gaps due to pieces not aligning perfectly) yielding approximately 110 Henries the calculated permeability was 525: If I'd very carefully interleaved and stacked each lamination, I would have expected the permeability to be in the multi-thousand range!

Taking this into another equation, we can calculate the magnetic field strength using this equation, also from link #1:

Bdc = (12.6 * uE * T * Idc) / (ML * 10000)

Where:

After the original assembly of the core, I had to disassemble the choke's laminations again to mount the end bells as shown in Figure 1, above. In the process I used a wooden block to more evenly seat the laminations: Between this and cinching the screws tightly, the gap between the E and I sections was slightly reduced and the measured inductance went up to around 75 Henries - a bit too high to prevent saturation at 200 mA according to our previous calculations. Adding a second piece of 10 mil insulating paper - for a total of 20 mils (0.5mm) of thickness (or 40 mils overall in the magnetic path) reduced the inductance to around 54 Henries as can be seen below in Figure 9.

Final thoughts:

For the time being - and since this is a prototype - I'll leave the design alone, but it brings up some points for the next time that I wind a similar choke:

Doing this would allow the use of a slightly heavier gauge of wire to be used on the same-sized bobbin to further decrease ohmic losses and increase current-handling capacity. In short, I suspect that something in the range of 1600-2000 turns of 27 AWG and a reduced air gap would yield something fairly close to a 10 Henry inductor with significantly reduced DC resistance (e.g. in the range of 55-75 ohms) with the current rating being restricted by the desired minimum inductance rather than the heat dissipated due to Ohmic losses.

At some point on the near-ish future, another such inductor will be wound but we have yet to determine the form it will take: Will it be as neatly wound as this, or will it be done so that the wires are allowed to cross at shallow angles. Will it have about as many turns as this choke or will it use a heavier conductor with fewer turns for less - but adequate - inductance?

Stay tuned!

The next phase of this project will be to wind a filament transformer.

|

| Figure 1: The finished choke with a rating of about 50 Henries at 200 milliamps, described below. Click on the image for a larger version. |

Why?

For some reason I have decided to go "old school" and, along with a friend (Bryan, W7CBM) we will each construct a two-channel single-ended triode audio amplifier using some old WWII vintage tubes (the details on this amplifier to be detailed in a later post.) To be clear, I'm not of the sort that really believes that the "tube sound" is best for various intangible reasons - in fact, I'm expecting that if it works better than expected, its performance will be worse than practically any other modern audio amplifier that I have in the ways that matter to most people (e.g. power efficiency, noise, hum, distortion, frequency flatness, phase - just name it!)

As it is often the case with a project like this, practicality is somewhat irrelevant: It is the experience of doing something that you have never done before - and learning from it - that will be the reward whether or not the project is ultimately successful. To be sure there will not likely be a cost savings in doing this and there certainly will not a time savings!

Diving into this project, we decided to do something that I'd not done for many years: Wind my own power transformers and chokes. As for the audio output transformers for this audio project we decided to forgo that task and get "store bought", proven transformers given our current level of experience.

Where to find useful information:

Interestingly, scant useful and credible information seems to be available on the GoogleWeb on this topic, but two sources that are useful are:

- Turner Audio(link) - These pages contain much practical advice on power and audio transformers and chokes. (Refer to the link "Power Transformers and Chokes" (link) and related pages linked from that page.)

- Homo-Ludens - Practical transformer winding(link) - While mostly about power transformers, this page also contain practical advice based on hands-on experience of winding, re-winding and reverse-engineering/rebuilding transformers. There is also another linked page "Transformers and Coils"(link) that has additional information on this topic.

|

| Figure 2: The NZ-1 "Hand Shake" winder (e.g. "hand cranked") winding machine, before it was mounted to a firm base. Click on the image for a larger version. |

A few other bits and pieces of information have been found but the above two seem to be some of the best, both written by people who have years of practical experience - and the pages include additional references to other sources.

Rummaging through some old amateur radio and electronics books I have been able to divine other details as well, but much of this information is rather generic and doesn't speak much about the use and capabilities of modern types of wire, insulation or core materials.

Getting the gear together:

Made mostly from cast steel, this device is about as simple as it can get: It has some gears that provide an 8:1 ratio for the hand crank (e.g. one revolution of the crank = 8 turns on the coil), a 5-digit turns counter (0-99999) and a spindle on which one would mount the bobbin, and it seems to be built "well enough" for the purpose, likely to last many hundreds of thousands of revolutions. This device has no wire-handling capability (e.g. nothing to hold the spool, guide the wire or provide tension) so those pieces would have to be constructed and/or improvised.

After the NZ-1 arrived I bolted it to a block of wood and for wire handling of the supply spool I made a simple wooden "A" frame holder (Figure 3), placing it on the workbench behind the winding machine.

By default, the crank is connected to a shaft that, via gears, results in eight turns on the coil with one turn of the crank. For practical reasons, winding a core like this needs a bit more precision and control and a 1:1 ratio is desired and the obvious place to relocate the crank is the upper shaft with the pulley, visible in Figure 2 on the upper-right corner of the winding machine.

While the shaft size is the same, attaching the crank at this point caused the crank's handle to hit the lower shaft to which the crank is usually connected! Fortunately I could attach the crank to the very end of the shaft and have it just barely clear the lower shaft where the crank would normally be attached for the 8:1 ratio: At some point I'll have made a metal piece made that will extend the shaft by a half inch (approximately 1cm) or so.

Also very important is the bobbin holder (Figure 4) constructed from scraps of paneling and "1x2" pieces of poplar. Because the core size is "E150" - which stands for "1.5", two pieces 1x2 wood (which are really 0.75"x1.5") fit very nicely within the bobbin. Glued to the end of the bobbin holder on one side is a scrap of paneling as an end-stop while on the other side, oriented by two finishing nails used as pins, are two more pieces of 1x2 glued together as the "other" end stop. Both the bobbin and the removable end stop are marked to provide a means of orienting the four faces of the bobbin and the removable piece also sports two screws around which wires that are brought out from the bobbin may be wound to keep them out of the way. Two more blocks of wood, cut to the internal length of the bobbin, are also available to compress the "bulge" that inevitably forms as wire is wound. Through the center of the bobbin holder was drilled a hole of the size appropriate to allow it to be slipped over the shaft of the winding machine. When mounted, the bobbin holder is held in by compression of the nut and it does not easily turn on its own.

While not the most elegant of solutions, this arrangement seems to work - provided that one takes care to prevent "overfeeding" of the wire and subsequent possible tangling of off-spooled wire caused by the inconsistent feed rate as one winds onto a square bobbin and the supply wire occasionally tries to wind itself around the piece of "allthread" on which the spool hangs!

The most important aspects of this minimal arrangement are:

- A means of automatically counting the turns laid down. While inductors are somewhat less critical in terms of keeping track of turns with absolute accuracy, when winding transformers you do not want to lose count at all!

- The bobbin itself being mounted on a stable, rotating platform about its winding axis.

- Being able to manually gauge the tension and guide the wire into the bobbin.

Because a choke is "simpler" to wind than a transformer, I decided to start with that.

The design goal of the choke was to provide at least 10 Henries of inductance with a current capacity of at least 200mA. The general rule of thumb for a modest-sized transformer or choke is to size the wire to 0.3 to 0.4 mm2 per amp (from references 1 and 2, above) which would imply that for 200mA the minimum wire would need a cross-sectional area of around 0.06mm2 which corresponds to #29 AWG.

Now we need to figure out (approximately) how many turns can fit on our bobbin.

The E150 bobbin that I would be using has an inside dimension of 41.5mm on a side and an outside dimension of 75.4mm on a side with a "width" of 53.3mm and based on this we calculate that the area of the bobbin's window is approximately 53mm wide and 17mm high, or about 901mm2.

Because the cross sectional area of #29 AWG wire, based on a 0.33mm diameter with insulation, is 0.086mm2 this implies that we could theoretically put around 10477 pieces of wire (or turns) in this 109mm2 space. Practically speaking, this is simply not possible since there is always going to be some "wastage" based on the fact that we will be laying round wires next to each other and there will be gaps in between. Typically, one would scale this calculation by a "fill factor" to accommodate such wastage with this factor typically being around 0.4 (e.g. 4191 turns) or as high as 0.5 (5239 turns) if one winds extremely carefully and neatly - and assuming no added insulation: Less careful winding can easily result in "fill factors" lower than 0.4.

Breaking this down differently we can calculate that across the width of the bobbin we should (theoretically) be able to put (53mm/0.33mm = 161) turns on each layer, but taking into account the practicalities of being able to get wire to lie snugly next to its neighbor we can more reasonably expect to achieve around 95% of this, or about 153 turns per layer - maybe slightly more if we are fastidious.

Since our bobbin window is 17mm "tall" we could theoretically expect to be able to stack 51 layers of 0.33 thick wire, but this also assumes both "perfect" stacking efficiency and the lack of any inter-layer insulation. If we presume that each layer contains a 0.33mm thickness of wire and 0.05mm thickness of insulation - a total of 0.38mm - we can then recalculate that it would take about (17/0.38) 44 layers of windings to fill the bobbin - again, assuming perfect stacking and no need for additional insulation.

For practical reasons we would want to fill our bobbin to only 70-90% "fullness" in order to be able to add the final covering insulation and connecting wires, so this would take or maximum layer count down to between 30 and 39 layers - again, assuming that we didn't need extra insulation anywhere.

If we take an average of 153 turns per layer, we could reasonably expect be able to put between 4590 and 5957 turns on this bobbin. Taking a median per-turn length of wire on the bobbin to be around 234 mm based on the size of the bobbin itself we can estimate that we'll need between 1074 and 1394 meters, or between 28 and 37% of our 5 pound spool.

Comment:

At this point I should have referred more closely to link #1, above, to determine the amount of inductance that the calculated number of turns would yield in a typical situation. To do this, I would have wound a known number of turns onto the bobbin and assembled the coil into a core and made inductance measurements so that the permeability - particularly that when an air gap was added (more on that later) - could be measured, but instead I simply bulldozed ahead and started winding turns! What this means is that I probably would have wound a coil with fewer turns and, possibly, heavier-gauge wire.

Starting the wind:

With the necessary parts (bobbins and core material being "E150" types from Edcor, the wire and polyimide insulating tape from other sources) I began to wind a choke - the simplest of the devices and (hopefully) hardest to screw up!

The general advice on winding transformers seems to be that it is best to assure that all wires are laid side-by-side on nice, even layers. By doing this one avoids one turn from crossing another and putting tremendous point-pressure on the insulation of the two wires as they cross. This advice hales from the days when wire was insulated with simple, comparatively fragile varnish that could be easily penetrated from vibration due to hum and thermally-related movement and by its softening at higher temperatures, but these days wire is available with much more durable insulation, so it seems to be permissible, with chokes, anyway, to allow wires to cross at shallow angles.

Since this was my first large power choke choke I decided to take the "neat, even layer" approach for the most part, but what this meant was that during each and every turn I would have to watch exactly where the wire turn lay, often scrunching it close to its neighbor if it shifted away and "un-crossing" it if it happened to overlay another. This also meant that after I finished winding every layer of approximately 150-156 turns I had to stop, temporarily tape the source wire to the bobbin to keep in from unraveling, apply a layer of 2-mil (0.5mm) polyimide tape over the top of the layer and then resume winding.

As is the case with such things, it is a bit more difficult than one might at first expect. For the first several layers I had to contend with the "lump" and the "gap" at the "start" end of the bobbin where the external wire was attached and I did this by filling in the void with very thin strips of cardboard laid down to match the width and height of the heavier, connecting wire. After several layers, the layers equaled the height of this "lump" and with the matching thickness of the cardboard strips, it disappeared, allowing me to more easily wind across the entire width.

After a dozen or so layers the windings started to form "ripples" caused largely by the fact that the polyimide tape overlapped in approximately the same place each time - a problem exacerbated by the fact that I had, at the time, only one width of tape, limiting the degree to which I could "stagger" the overlap. The biggest problem with this was not necessarily asthetics, but the fact that the as the wire was wound it tended to slip into the trough of the ripple, making it very difficult to maintain evenness and the nice, side-by-side wire lay for which I was striving and with each layer, these irregularities grew!

What I had to do was to fold over some of the tape in half (sticky side facing outwards) to fill in some of the dips and on the square "corners" of the bobbin I started to strategically add small bits of tape to level it out as it was there that the slippage was most likely to occur. As I got into 10s of layers, some of the troughs seemed to resist the attempts at leveling so I carefully resorted to putting several turns of wire atop each other at shallow angles to help even the surface: Only a tiny fraction of the turns are wound in this way.

The lesson here is to have on hand multiple widths of tape so that the overlaps may be staggered. What would have also been handy would have been to have on-hand some pieces of MNM ("Nomex" (tm)) insulating sheets to cut into strips to fill the voids. It would have also been very help to have some tape that was exactly as wide as the bobbin, but such a specific width is not likely to be commercially available.

The results:

Based on the DC resistance - around 277 ohms - this represents approximately 3384 feet (1031 meters) of wire - a bit more than a quarter of the 5 pound spool. Carefully drilling another hole in the bobbin I attached the "finish" wire to the outside of the coil, insulated it and taped it securely into place.

By itself (no core) the inductance of the 4905 turns on the bobbin measured out at approximately 884 millihenries and when the core was installed - butt-stacked, but not carefully aligned - this increased to over 110 Henries: If I had carefully interleaved all 109 E-I laminations and properly seated each piece this value would have likely been much higher!

Preventing core saturation:

Because this is intended to be used as part of a "choke input" high voltage power supply one must take into account the fact that DC current will flow through the choke, magnetizing the core material. One property of practically any ferromagnetic material - including the steel used in the core of this choke - is that if the magnetic field exceeds a certain point, the core will saturate and the permeability (and the inductance) will drop! While there are chokes that are designed to do this (e.g. "swinging" chokes - those that have inductance that, by design, drops with increased current) it was desired that this choke's inductance be more consistent.

The most common way to control this effect is to intentionally reduce the permeability of the core overall by the introduction of an air gap which breaks up the magnetic lines of force: The larger the gap, the greater the reduction. The trick here is to reduce the permeability - and thus the level of magnetization - to the level that the core does not saturate at the desired current, but not too much more.

Fortunately, there are some equations that help us calculate things like this. Knowing that the core material that I am using ("M6" Grain-Oriented Silicon Steel) will safely operate at 1.6-1.7 Tesla (16000-17000 Gauss) I could crunch some numbers based on what I already knew.

Taking the following equation from link #1 (the Turner audio web pages), above:

uE = (109 * ML * L) / (T2 * Afe)

Where:

- uE = The permeability of the core

- ML = Iron path length in mm (approx. the width plus length of a single assembled E-I section)

- L = The measured inductance in Henries

- T = Number of turns

- Afe = The cross-sectional area of the iron inside the bobbin in mm2

With the temporary butt-stacked arrangement (e.g. full of small gaps due to pieces not aligning perfectly) yielding approximately 110 Henries the calculated permeability was 525: If I'd very carefully interleaved and stacked each lamination, I would have expected the permeability to be in the multi-thousand range!

Taking this into another equation, we can calculate the magnetic field strength using this equation, also from link #1:

Bdc = (12.6 * uE * T * Idc) / (ML * 10000)

Where:

- Bdc = Magnetic field, in Tesla.

- uE = The permeability of the core.

- T = Number of turns.

- Idc = DC current, in amps - the target being 0.2 amps for this design.

- ML = Iron path length in mm, as above

After the original assembly of the core, I had to disassemble the choke's laminations again to mount the end bells as shown in Figure 1, above. In the process I used a wooden block to more evenly seat the laminations: Between this and cinching the screws tightly, the gap between the E and I sections was slightly reduced and the measured inductance went up to around 75 Henries - a bit too high to prevent saturation at 200 mA according to our previous calculations. Adding a second piece of 10 mil insulating paper - for a total of 20 mils (0.5mm) of thickness (or 40 mils overall in the magnetic path) reduced the inductance to around 54 Henries as can be seen below in Figure 9.

Final thoughts:

For the time being - and since this is a prototype - I'll leave the design alone, but it brings up some points for the next time that I wind a similar choke:

- Now that I have some actual, practical numbers for this particular core material and the effects of gapping, I should be able to predict ahead of time with reasonable accuracy the outcome of a particular winding configuration. Using a different core (size, material) I would be certain to do a "test winding" to divine its aspects prior to finalization of the design.

- 51 Henries is a bit higher than is typically used for a power supply choke, providing an inductive reactance of around 38k Ohms at 120 Hz, the AC ripple frequency for full-wave rectified 60 Hz mains. (It would be about 32k for 100 Hz on 50 Hz mains.) In general, the higher the inductance, the better - provided care is taken to avoid resonances related to the filter capacitance and the load. The higher inductance will reduce the ripple - particularly important for single-ended triode amplifiers.

- The design goal of the choke was to handle at least 200mA. With a DC resistance of 277 ohms approximately 55 volts will be lost across the choke due to this resistance at the design current, implying a heat load of approximately 11 watts (resistive only and not including core losses) - an acceptable amount for a core this size. The voltage drop - while higher than desired - can be simply accepted and/or taken into account when designing and building the high-voltage plate transformer and associated supply.

- A more conventional inductance for a choke-input power supply is in the area of 3-10 Henries, so this design is likely an overkill - but then again, reducing the ripple on the power supply of a single-ended triode amplifier is not a bad thing!

Doing this would allow the use of a slightly heavier gauge of wire to be used on the same-sized bobbin to further decrease ohmic losses and increase current-handling capacity. In short, I suspect that something in the range of 1600-2000 turns of 27 AWG and a reduced air gap would yield something fairly close to a 10 Henry inductor with significantly reduced DC resistance (e.g. in the range of 55-75 ohms) with the current rating being restricted by the desired minimum inductance rather than the heat dissipated due to Ohmic losses.

At some point on the near-ish future, another such inductor will be wound but we have yet to determine the form it will take: Will it be as neatly wound as this, or will it be done so that the wires are allowed to cross at shallow angles. Will it have about as many turns as this choke or will it use a heavier conductor with fewer turns for less - but adequate - inductance?

Stay tuned!

The next phase of this project will be to wind a filament transformer.